Membrane Electrode Assembly Paper

Membrane Electrode Assembly Paper Specification

- Product Type

- Membrane Electrode Assembly Paper

- Usage

- Fuel Cell Applications

- Material

- Proton Exchange Membrane with Carbon Supported Catalyst

- Capacity

- High Electrochemical Performance

- Nominal Capacity

- Optimized for Maximum Power Density

- Terminal

- No Direct Terminal, Assembly-based Connection

- Sealed Type

- Semi-Sealed

- Voltage

- 1.0 V to 1.2 V per Cell

- Surface Finishing

- Uniform Catalyst Coating

- Board Thickness

- 0.2 mm to 0.4 mm

- Size

- Standard and Custom Sizes Available

- Dimension (L*W*H)

- Customizable, Commonly 60mm x 60mm x 0.3mm

- Weight

- Approx. 0.5 g (depends on size)

- Membrane Type

- Nafion or Equivalent PEM

- Electrode Type

- Pt/C Carbon Paper Electrode

- Flexibility

- Flexible for Lamination and Assembly

- Catalyst Loading

- 0.3 0.6 mg/cm

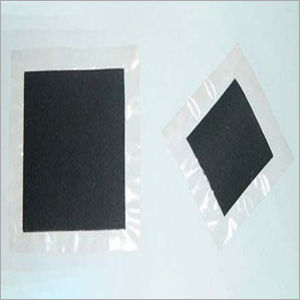

- Packaging

- Vacuum Sealed to Preserve Integrity

- Humidity Tolerance

- Up to 95% RH

- Application

- PEM Fuel Cells, Hydrogen Fuel Cells, Electrolyzer Cells

- Water Management

- Optimized for Hydration and Water Retention

- Operating Temperature

- Up to 80C

- Porosity

- High Gas Diffusion Rates

- Shelf Life

- 2 Years (unopened)

- Proton Conductivity

- 0.10 S/cm

- Assembly

- Ready for Direct Integration into Fuel Cell Stack

- Storage Conditions

- Cool, Dry Environment (<25C)

About Membrane Electrode Assembly Paper

We are in the everlasting fashion of making good quality Membrane Electrode Assembly Paper which is an assembled stack of proton exchange membranes and flat plate electrode. It is used in fuel cells and electrolyzes. We make and test it with right manner in place. We deliver it at leading market prices.

High Performance for Fuel Cells

The MEA paper is designed for use in PEM fuel cells and hydrogen fuel cells, offering optimized proton conductivity and water retention. Suitable for high humidity environments (up to 95% RH) and a wide range of operating temperatures, it provides exceptional electrochemical output and reliability for energy generation and research purposes.

Ready-to-Use and Customizable

This assembly arrives vacuum-sealed for unmatched integrity, with flexible options for lamination and direct stack integration. Multiple size choices, including the common 60mm x 60mm x 0.3mm format, ensure compatibility for various system designs in both standardized and unique applications.

Advanced Water Management

Engineered for optimal hydration, the MEA paper maintains high water retention and efficient gas diffusion. The semi-sealed format and uniform catalyst coating offer robust performance throughout its two-year shelf life, guaranteeing consistent output for continuous or intermittent operation in fuel and electrolyzer cells.

FAQs of Membrane Electrode Assembly Paper:

Q: How is the Membrane Electrode Assembly Paper integrated into fuel cell stacks?

A: The MEA paper is designed for direct integration into fuel cell stacks, thanks to its flexible construction and customizable sizing. It fits seamlessly between bipolar plates, requiring only standard stacking procedures without any additional terminal connections.Q: What applications can this MEA paper be used for?

A: It is suitable for proton exchange membrane (PEM) fuel cells, hydrogen fuel cells, and electrolyzer cells. The assembly is ideal for both research and commercial energy generation systems where high electrochemical performance is critical.Q: When should the MEA paper be replaced or used by?

A: The product has a recommended shelf life of two years when unopened and stored under cool, dry conditions below 25C. Once installed, replacement depends on operating hours and application-specific degradation profiles.Q: Where should the MEA paper be stored before use?

A: Storage in a cool, dry environment at temperatures below 25C is essential. The vacuum-sealed package protects the assemblys integrity, and high humidity (up to 95% RH) can be tolerated only during operational use, not storage.Q: What is the process for handling and assembling the MEA paper?

A: Carefully remove the MEA from its vacuum-sealed packaging and avoid damaging the uniform catalyst layer. Immediately integrate into the cell stack as per standard procedures to maintain hydration and avoid contamination.Q: What benefits does optimized water management provide?

A: Optimized water management enhances both proton conductivity and gas diffusion, reducing risks of membrane dehydration and maximizing fuel cell efficiency and longevity. This ensures reliable power output across varying humidity and operational conditions.Q: What are the packaging and size options available for the MEA paper?

A: The assembly is vacuum-sealed to maintain quality and is available in both standard (e.g., 60mm x 60mm x 0.3mm) and custom sizes. Manufacturers, suppliers, and traders in India can provide dimensions tailored to specific project requirements.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in MPL Coated Carbon Paper Category

Carbon Cloth

Usage : Filtration, Electrodes, Energy Storage, Composite Reinforcement

Size : Custom sizes available

Surface Finishing : Matte or Glossy

Dimension (L*W*H) : Standard widths: 100 cm or customizable; length as required

Weight : Typically 200400 g/m

Carbon Fibre Paper

Usage : Industrial Filtration, Battery Electrodes, Fuel Cells

Size : 500mm x 500mm

Surface Finishing : Smooth, Matt Finish

Dimension (L*W*H) : 500mm x 500mm x 0.5mm

Weight : Approx. 110 g/m

|

DURALYST ENERGY PRIVATE LIMITED

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry